Metal Bending Ipswich

Delivering precise laser cutting and metal fabrication with accuracy, speed and reliability – contact us today for quotes and custom projects.

100%

Locally Owned & Operated

Modern

Laser Cutting Technology

One-Off to Bulk

Project Capability

Custom Design Solutions

Advanced Metal Technology

End-To-End Fabrication

Easy Quote Process

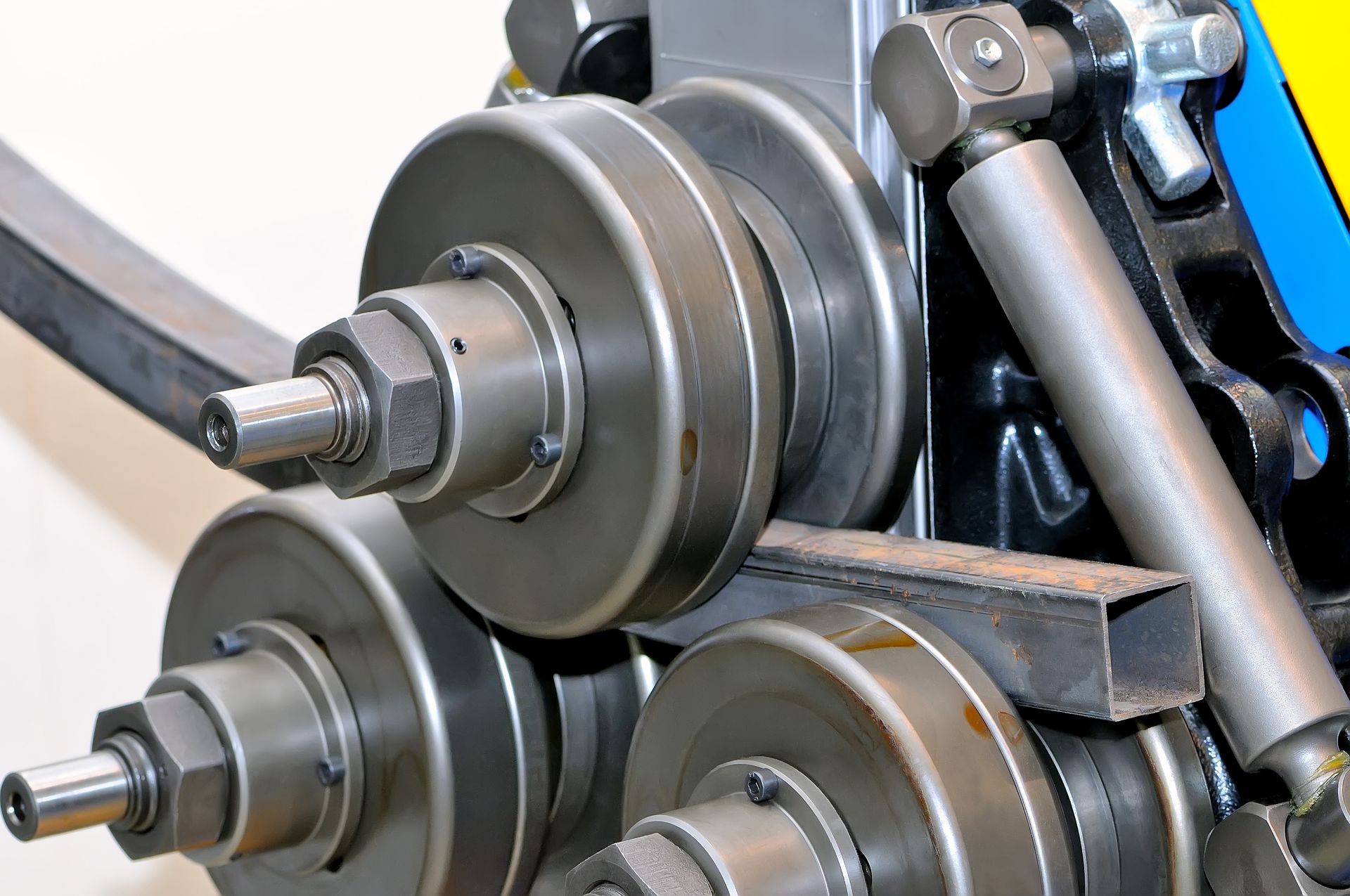

Strong Bends, Perfect Form

Metal bending and forming is all about precision – one wrong angle can throw an entire job off. That’s why we take the time to set up every bend right from the start. At Bryants Laser Works in Ipswich, we use modern press brakes and forming equipment to deliver consistent, accurate results across steel, aluminium and stainless steel. Whether it’s for structural components, industrial frames or custom projects, every bend is clean, consistent and ready for fabrication or assembly.

We understand the pressure of deadlines and the importance of quality. Each job is completed efficiently and checked for accuracy before it leaves our workshop. Call 07 3543 4735 to talk through your next bending or forming project today.

Frequently Asked Questions

What’s the difference between metal bending and forming?

Bending shapes a metal sheet along a straight axis, while forming creates more complex curves or angles. Both are essential in fabrication, allowing parts to fit precisely and maintain strength without the need for extra joins or welds.

Can you bend and form all types of metal?

Most metals can be bent or formed, including aluminium, stainless steel and mild steel. Each material reacts differently depending on thickness and hardness, so settings are adjusted to prevent cracking or uneven bends while keeping the finish smooth.

Why is professional metal forming important?

Precision forming ensures every component fits as intended, avoiding costly delays or rework later. Skilled forming also maintains the metal’s structural integrity, giving you parts that perform well under stress and last longer in their final use.

Enquire Now

Thank you for contacting Bryants Laser Works.

We will get back to you as soon as possible.

Please try again later.

Built by Skill, Backed by Precision

Our team understands how different metals behave under pressure and heat, adjusting angles and force to get that perfect curve or fold. We can work from drawings, CAD files or templates, making it easy to turn your designs into finished components that fit the first time.

What sets us apart is the consistency of our results and the care we put into every piece. From single prototypes to full production runs, we deliver strong, reliable bends that look as good as they perform. Every job gets the same attention to detail, from setup to final inspection, so you get consistent, professional results every time.